Lifetime test system for glow control units, glow plugs and heaters.

The product line Lifetime Test System (LDTS) is a product line whose devices are used for testing glow control units, glow plugs and auxiliary heaters. The structure is based on a work table, on which a water-cooled rack is mounted to hold the glow plugs, and the measurement cabinets. The overall system thus consists of the work table, the control cabinets with the measurement technology, an industrial PC, as well as the structure for the glow plugs and the heat sinks of the output stages of the electronic loads. The system is available with 24, 48 or 96 load channels and as a laboratory setup.

The measurement technology is based on commercially available components, namely 1-3 multi-I/O cards from National Instruments with 64 A/D channels each.

For the power supply, 4 or 8 delta constants with 200A each are installed, which are controlled via the IPC and monitored via a controller-controlled I/O module.

Furthermore, in-house developed bus simulations are integrated as motor control unit simulations for communication with the DUTs. These support CAN and Lin bus, as well as one and two wire connections.

In addition, specially developed electronic loads for simulating glow plug behavior (resistance characteristic) are built in.

The following key data are fulfilled by the system:

- 17V / 40A per load channel

- maximum 800 or 1,600A in total

- 6, 12 or 24 glow control units simultaneously

- total of 24, 48 resp. 96 load channels

- communication with the DUTs via different protocols (EDC, BSD, CAN, extented CAN, LIN)

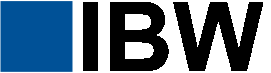

The test sequence can be freely configured, the following commands are available here:

- Send annealing request (annealing on/off)

- Set climatic chamber (temperature and humidity)

- Definition of the annealing phases

- Wait (for time or for trigger signal)

- loop for repetition e.g. of annealing phases

- Set constant voltage

- Switch ignition (Ignition 0 and 1)

- Set air mass flow for auxiliary heater

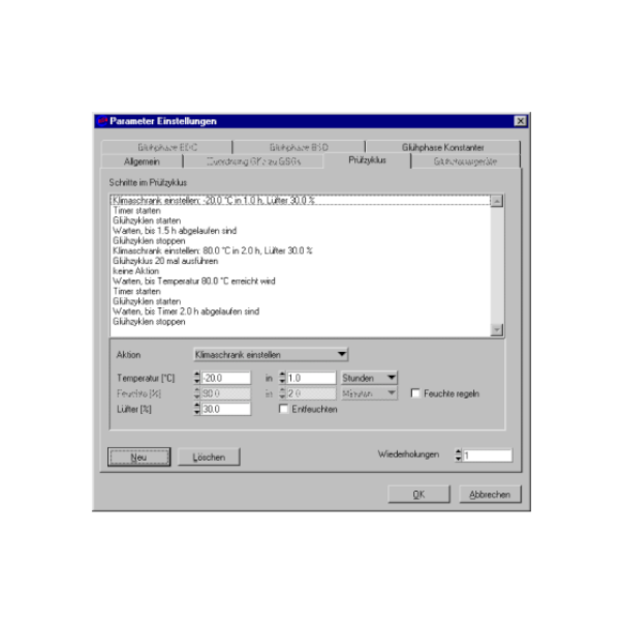

The software also has a diagnostic function with which the connected devices and components can be operated and visualized.

Here the control of the following components is possible:

- Fan (for defined cooling of the glow plugs))

- climatic cabinet

- electronic load

- constant setting

- glow demand to the test specimens

- Control of air mass flow for auxiliary heater

In the lower part of the window all CAN messages are visualized on the test system CAN.

The service life test system is suitable for testing a wide variety of glow control units. The different types are connected via a coded connection cable, which can be exchanged quickly and easily.

The order registration takes place via at the user interface. After selecting the desired parameter set, the test sequence can be started. The selected DUT type is checked by the software via a coding in the connection cable.